Mechanical engineering

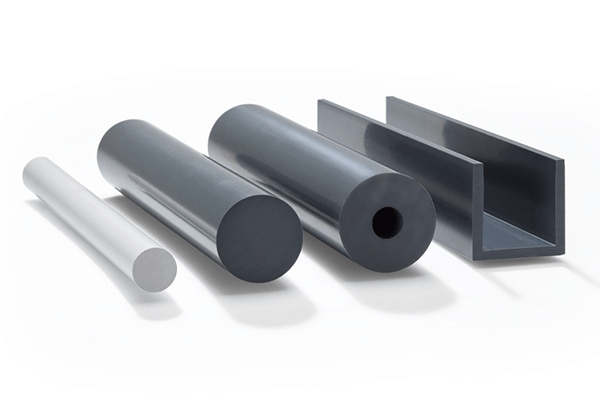

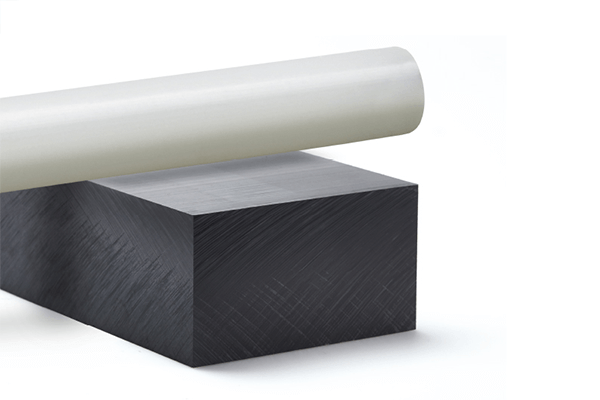

Today, components for mechanical applications in classical mechanical engineering are often produced by chip removal machining from thermoplastic semi-finished products, as they can offer advantages over conventional materials. Due to the excellent machinability and the wide range of standard, technical and high-performance plastics, GEHR is able to offer the optimum semi-finished product for many applications as a starting material for further processing, which also has a high resistance to chemicals or good sliding properties.

You decide on the main emphasis of required mechanical (strength, rigidity, toughness and hardness), thermal (Vicat, heat deflection temperature, linear expansion) or electrical properties (volume resistivity, surface resistance, dielectric strength), regardless of whether you want to realise your application with an unreinforced, a fibre-reinforced or a sliding-modified material. Special materials or material mixtures can also be used in customised solutions, so that applications used in certain limit areas can also be attended to.

Properties

Sliding properties

In order to reduce friction losses as far as possible in mechanical engineering processing, mainly materials with good sliding properties are used in this sector.

Chemical resistance

Products in mechanical engineering can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Thermal resistance

Processing machines in the mechanical engineering can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

Mechanical strength

Polymer materials are often used as substitutes for other materials. Therefore, there are also increased demands on the strength here.

Construction material

Materials that require a high degree of freedom in design are often selected from this material group because of their diverse properties.

Radiation resistance

Radiation-resistant materials must be used when components made from them come into contact with natural radiation (outdoor use on earth or in space) or artificial high-energy radiation (applications where, for example, a germ-free to low-germ surface is required.

Our products for the Mechanical engineering

You can reach us

Tel: +49 621 87 89 - 0

Fax: +49 621 87 89 – 200

GEHR GmbH

Casterfeldstr. 172

68219 Mannheim

Germany

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

Facilities

Our facilities and sales offices you find

here.