Food Industry

Special applications usually also require special approvals. This is also the case in the food processing industry. Components which are intended for usage here must comply with the statutory European regulations (1935/2004/EC, 10/2011/EC and 2023/2006/EC), and often also with the demanding raw material specifications for food contact issued by the US American authority (FDA).

Highest demands on our plastics

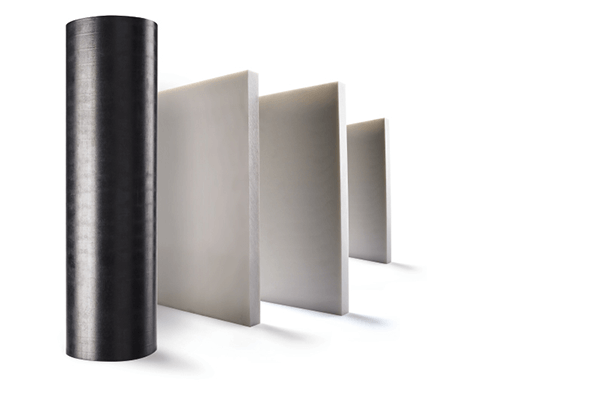

However, the various requirements can be very different. They range from long-term contact in classic tank production to components used in short-term contact in conveyor technology or feed products. The above approvals are proof that migration values set out in the regulations have been met and good manufacturing practice has been followed for materials and parts intended to come into contact with food.

The traceability of our semi-finished products to the production processes and the raw materials used is achieved through our internal production batch identification, which is applied to each semi-finished product label. The migration tests are carried out at different temperatures and different contact times as well as with different chemical agents in an accredited testing laboratory in accordance with the regulations detailed above. GEHR offers a large number of different materials from its standard delivery programme and customised solutions programme.

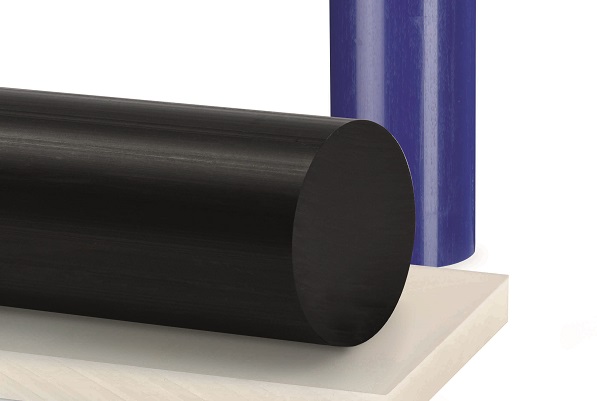

In addition to the approvals detailed above, our semi-finished products made of thermoplastic materials in the group of standard, technical and high-performance plastics also boast various additional advantages such as blue-coloured semi-finished products that can be optically detected.

Properties

Approvals...

…in accordance with the European Food Contact Regulation 10/2011/EC

During the production process all GEHR semi-finished products receive a label with the material designation, unique GEHR article and production number as well as an encoded bar code. Based on the production number, each product can be clearly be assigned to the respective process, raw material, production date, etc. GMP as part of the QMS is thus guaranteed.

Sliding properties

In order to reduce friction losses as far as possible in food and drinking water processing, mainly materials with good sliding properties are used in this sector.

Chemical resistance

Products in food processing can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Blue colour for optical detection

Since there are only very few foodstuffs of blue natural colour, plastic components made of blue dyed semi-finished products help with the additional optical detection. Furthermore, this colour offers a good contrast to deposits of harmful substances.

Hot water resistance

In addition to the use of chemicals in the food processing industry, hot water is often used for cleaning. For this reason, the relevant materials must have sufficient resistance against this medium.

Thermal resistance

Processing machines in the food industry can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

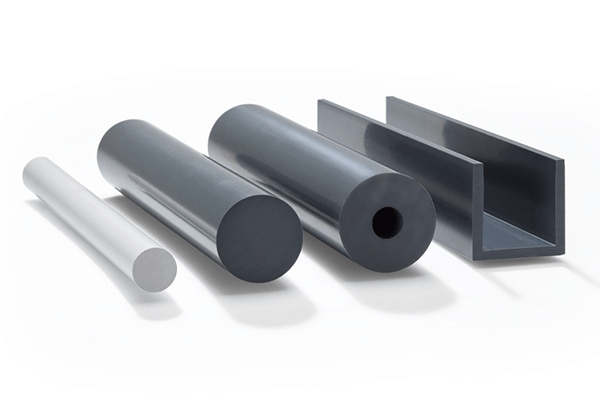

Our Products for the food industry

You can reach us

Tel: +49 621 87 89 - 0

Fax: +49 621 87 89 – 200

GEHR GmbH

Casterfeldstr. 172

68219 Mannheim

Germany

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

Facilities

Our facilities and sales offices you find

here.