Chemical apparatus engineering

Many applications are in direct contact with environmental impacts that either cannot be excluded or can be very differently structured (high-energy radiation, salts, oxidants and detergents, wet systems …). Often these external influences are of a chemical nature, against which selected component materials must be resistant.

The use of metals (structural steel or aluminium) is often unsuitable or requires expensive alloys. Many plastics, on the other hand, have a significantly higher chemical resistance than metallic materials due to their physical structure and enable the production of components with a very low risk of corrosion.

The right selection of plastic materials can clearly enhance the oxidative stability (for example against nitric acid, sulphuric acid, hypochlorous acid, chloric acid or peracetic acid) as well as the chemical stability in general (acids, alkaline solutions, fats, oils, disinfectants and solvents). This extends the service life of the application and reduces the costs for maintenance or component replacement.

Properties

Chemical resistance

Products in chemical apparatus engineering can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Thermal resistance

Processing machines in the chemical apparatus engineering can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

Mechanical strength

Polymer materials are often used as substitutes for other materials. Therefore, there are also increased demands on the strength here.

Hot water resistance

In addition to the use of chemicals in the Chemical Apparatus Engineering industry, hot water is often used for cleaning. For this reason, the relevant materials must have sufficient resistance against this medium.

Construction material

Based on the wide variety of property profiles of plastics, the industrial sectors are gaining increasing importance. The variety and combination possibilities of different polymers open up a wide range of possible applications as construction material. Regardless of the type of connection, the thermal requirements, the chemical resistance or the necessary approval of the individual application, the extensive range of polymer materials offers a solution for almost every problem.

Radiation resistance

Depending on the respective application, polymer materials can come into contact with a wide variety of radiation types. These can range from daylight to infrared and ultraviolet rays or exposure to radioactive radiation and are referred to as electromagnetic radiation. The material resistance can vary from wavelength to wavelength. The shorter the wavelength range that comes into contact with the component, the greater the risk of damage to the plastic. Therefore, appropriate knowledge is indispensable for choosing the right material for example for components used in the aerospace industry or in medical technology applications, such as radiation therapy or the sterilisation of components, since radiation impairs elasticity and toughness.

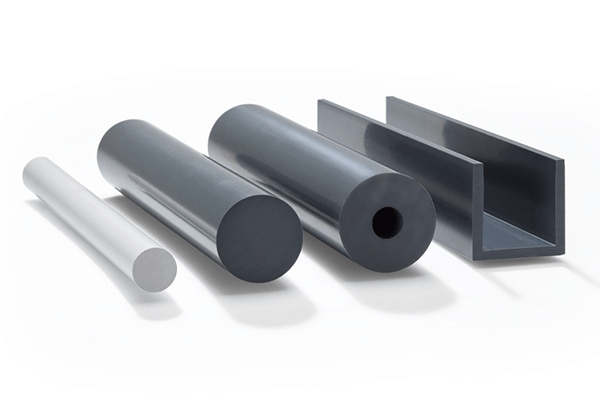

Our products for the Chemical Apparatus Engineering

You can reach us

Tel: +49 621 87 89 - 0

Fax: +49 621 87 89 – 200

GEHR GmbH

Casterfeldstr. 172

68219 Mannheim

Germany

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

Facilities

Our facilities and sales offices you find

here.