Electrical industry

Applications in the electrical industry are often combined with self-extinguishing properties of the material used, without the need to add flame retardant additives to the source material. This prevents unwanted blooming during use and thus impairment of the material properties.

Good insulation properties, high dimensional stability, low moisture absorption, good printability for labelling, high thermal stability and high resistance to various aggressive and abrasive chemicals, good machinability and many other features are all required without being mentioned in detail every time.

Properties

Chemical resistance

Products in electrical industry can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Thermal resistance

Processing machines in the electrical industry can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

Mechanical strength

Polymer materials are often used as substitutes for other materials. Therefore, there are also increased demands on the strength here.

Construction material

Based on the wide variety of property profiles of plastics, the industrial sectors are gaining increasing importance. The variety and combination possibilities of different polymers open up a wide range of possible applications as construction material. Regardless of the type of connection, the thermal requirements, the chemical resistance or the necessary approval of the individual application, the extensive range of polymer materials offers a solution for almost every problem.

Electrical conductivity

Some industrial applications require materials which are suitable to protect components made of these materials thanks to their good electrical discharge capacity or to prevent charge carrier jumps

Flame-retardant

Most polymer materials are carbon-based plastics and therefore belong to the field of organic chemistry. These materials are usually flammable. In areas where there is a risk of fire or explosion, such as the paint and varnish industry, dust-generating industry, electronics industry and chemical industry, these materials must therefore be modified accordingly in order to reduce or even prevent spontaneous combustion or electrostatic charging.

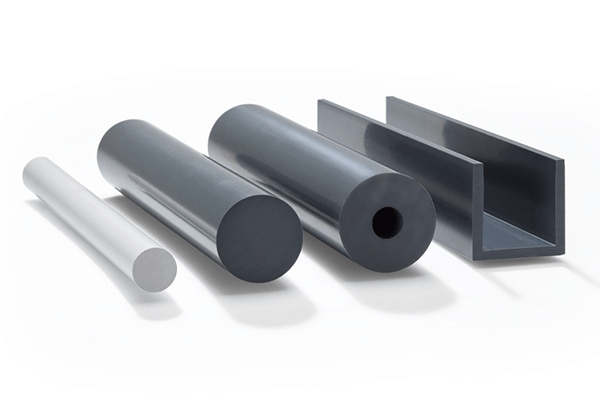

Our products for the electrical industry

You can reach us

Tel: +49 621 87 89 - 0

Fax: +49 621 87 89 – 200

GEHR GmbH

Casterfeldstr. 172

68219 Mannheim

Germany

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

Facilities

Our facilities and sales offices you find

here.