Oil and gas industry

Components to be used in the oil and gas industry frequently have to meet special requirements. Often high temperatures have to be withstood and mechanical strength combined with high toughness and chemical resistance is indispensible in order to meet the unusual and demanding requirements of this industry. Selected materials from our range of technical plastics and high-performance polymers are used here. Aggressive application environments combined with small component sizes pose similar challenges to the materials as homogeneous structure and high dimensional stability at alternating temperatures.

Properties

Sliding properties

In order to reduce friction losses as far as possible in the oil and gas industry, mainly materials with good sliding properties are used in this sector.

Chemical resistance

Products in the oil and gas industry can be acidic, alkaline or neutral. Materials used here must be able to withstand these contacts. Chemicals are also used for cleaning the production systems. Therefore, the machine components must also meet the requirements.

Thermal resistance

Processing machines in the oil and gas industry can be exposed to very low temperatures (in the cooling process) and to very high temperatures (in the cooking phase), which the components must withstand for a long time. Therefore, the appropriate suitability of the material is absolutely indispensable.

Mechanical strength

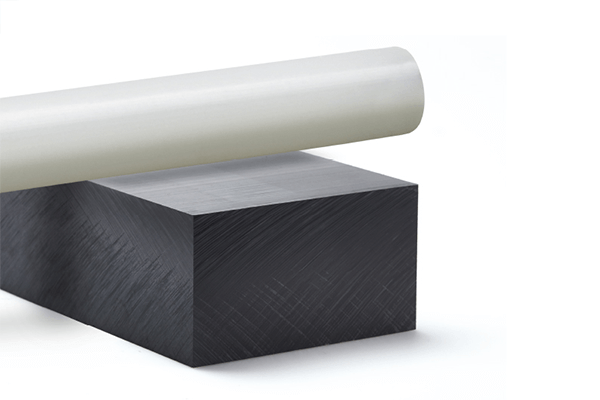

Polymer materials are often used as substitutes for other materials. Therefore, there are also increased demands on the strength here.

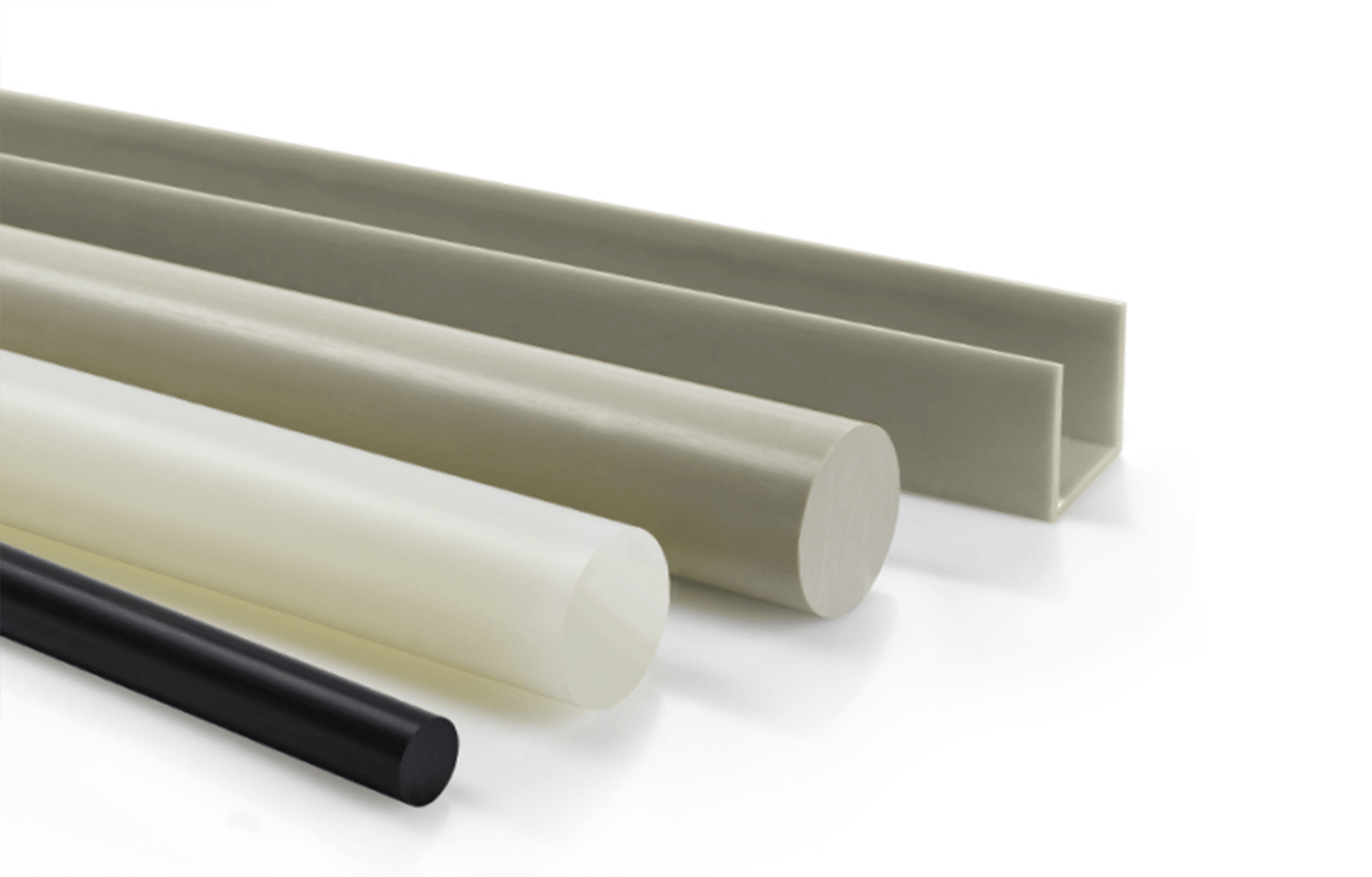

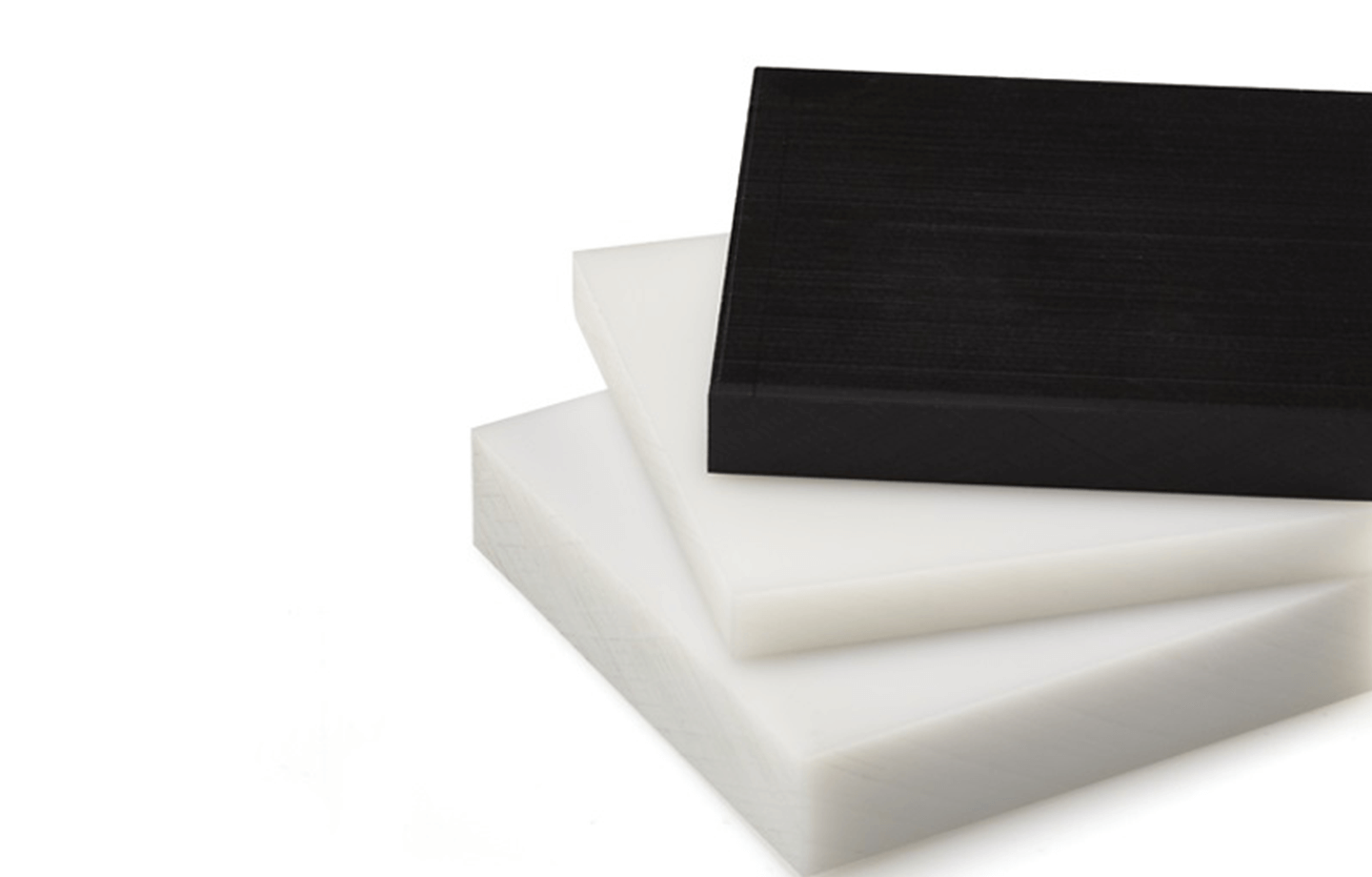

Construction material

Based on the wide variety of property profiles of plastics, the industrial sectors are gaining increasing importance. The variety and combination possibilities of different polymers open up a wide range of possible applications as construction material. Regardless of the type of connection, the thermal requirements, the chemical resistance or the necessary approval of the individual application, the extensive range of polymer materials offers a solution for almost every problem.

Electrical conductivity

Some industrial applications require materials which are suitable to protect components made of these materials thanks to their good electrical discharge capacity or to prevent charge carrier jumps.

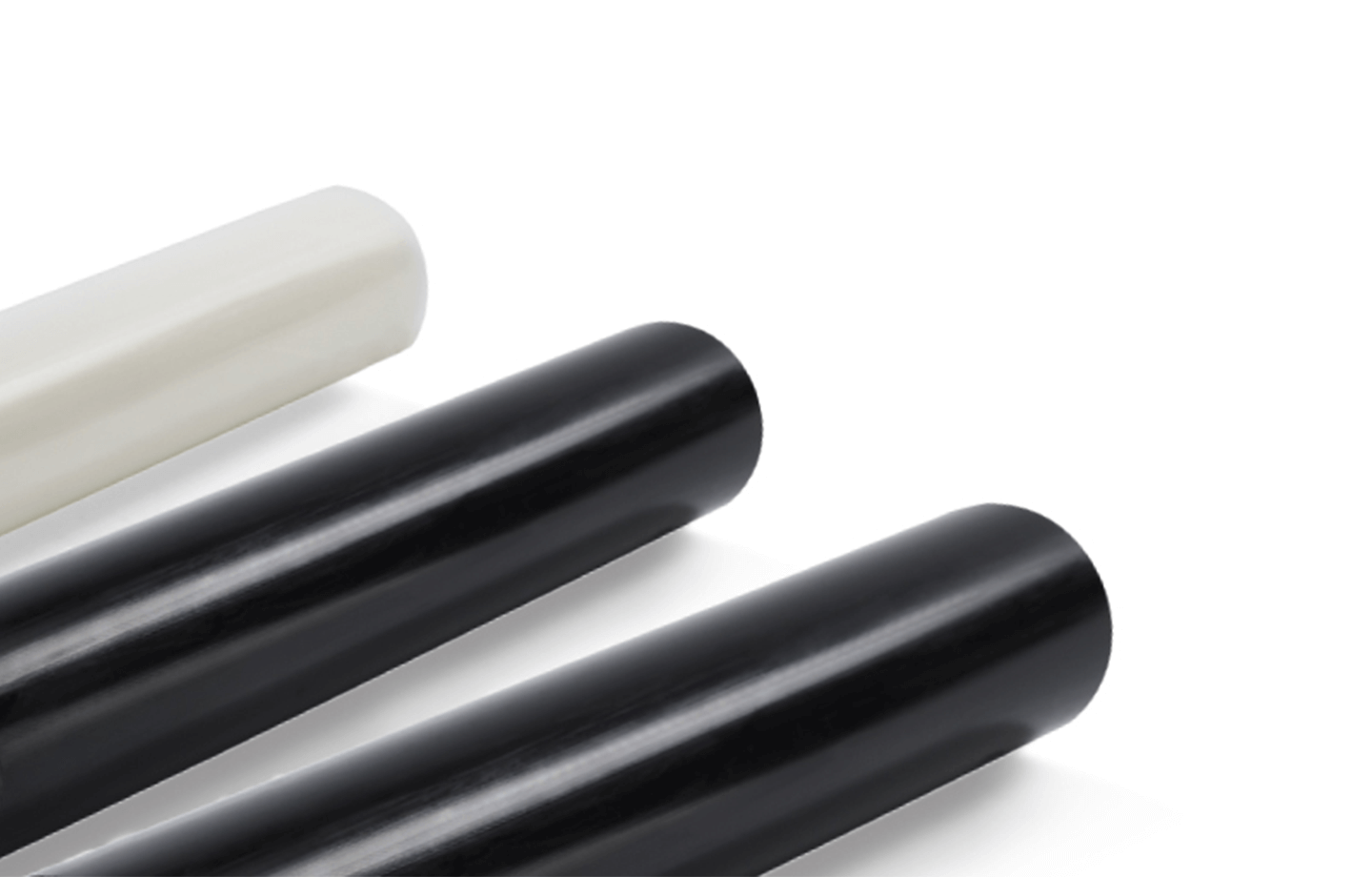

Our Products for the Oil and gas industry

You can reach us

Tel: +49 621 87 89 - 0

Fax: +49 621 87 89 – 200

GEHR GmbH

Casterfeldstr. 172

68219 Mannheim

Germany

You’re interested in our materials or you have a question about a particular product?

Please send us an e-mail:

or use our contact form.

We will get in touch with you as soon as possible.

Facilities

Our facilities and sales offices you find

here.